Direct-to-Film (DTF) transfers offer an eco-friendly and efficient printing solution for custom apparel. Using water-based inks and sustainable transfer films, DTF minimizes waste and harmful chemicals compared to traditional methods. It streamlines production, reduces turnaround times, and enhances product durability, making it ideal for on-demand orders like DTF printed t-shirts and personalized hoodies. Leading manufacturers offer biodegradable or recycled content films, enabling businesses to order DTF transfers while minimizing their environmental impact.

“Unleashing the environmental benefits of fast DTF transfers, this article delves into the eco-friendly facets of a process that’s revolutionizing printing. From understanding the core principles of Direct to Form (DTF) transfers to exploring sustainable materials and cutting-edge waste reduction techniques, we uncover how these advancements make ordering DTF transfers a responsible choice. Discover how modern innovations prioritize environmental stewardship without compromising quality.”

- Understanding DTF Transfers: The Eco-Friendly Process

- Sustainable Materials: A Key Component in DTF Printing

- Reducing Waste: Innovations in Fast DTF Transfers

Understanding DTF Transfers: The Eco-Friendly Process

Understanding DTF Transfers: The Eco-Friendly Process

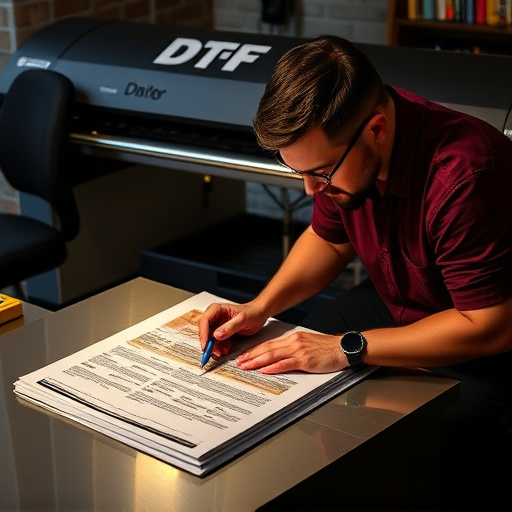

DTF (Direct to Film) transfers offer a revolutionary approach to printing on various materials, especially in the context of eco-friendly practices. This method eliminates the need for intermediate steps and harmful chemicals often used in traditional printing techniques. When you Order DTF Transfers, the process involves applying design directly onto a thin film, which is then transferred onto the desired substrate—be it fabric, wood, or plastic. This innovative approach streamlines production while minimizing waste.

By opting for DTF printing for hoodies or other materials, businesses and individuals can significantly reduce their environmental footprint. Direct to film printers use water-based inks, ensuring minimal chemical runoff during the printing process. Furthermore, dtf transfer film is designed for efficient application, reducing material wastage. This eco-conscious method not only enhances product quality but also contributes to a more sustainable future.

Sustainable Materials: A Key Component in DTF Printing

In the realm of eco-friendly printing, Sustainable Materials play a pivotal role in DTF (Direct to Fabric) transfers. When it comes to Order DTF Transfers, the choice of raw materials significantly impacts both the environmental footprint and the quality of the final product. Many leading manufacturers now offer DTF transfer films crafted from biodegradable or recycled content, reducing waste and pollution associated with traditional printing methods.

These sustainable materials not only contribute to a greener production process but also enhance the overall durability of the bulk DFT shirt production. By utilizing eco-conscious options, businesses can meet the growing demand for environmentally friendly apparel without compromising on style or performance. This shift towards sustainability is a game-changer, ensuring that fashion keeps pace with environmental responsibility.

Reducing Waste: Innovations in Fast DTF Transfers

The fast DTF (Direct-to-Film) transfer process has revolutionized custom apparel printing, offering a more efficient and eco-conscious alternative to traditional methods. One of its key environmental benefits lies in waste reduction. With advancements in technology, modern DTF printers now utilize precision-engineered nozzles that deposit ink directly onto the substrate, minimizing excess material use. This precise application means less wasted ink and film, which is particularly significant for businesses producing custom, on-demand orders like DTF printing for t-shirts or crafting unique direct to film personalized hoodies.

Furthermore, the streamlined nature of DTF transfers allows for faster production times. By eliminating the need for complicated screen printing processes or cutting and weeding, businesses can swiftly fulfill customer requests, reducing the carbon footprint associated with longer production cycles. This efficiency is a game-changer for small businesses and entrepreneurs looking to offer personalized items, ensuring they can order DTF transfers quickly and sustainably.

In conclusion, fast DTF transfers offer a sustainable solution for businesses seeking eco-friendly printing methods. By understanding the process, leveraging sustainable materials, and embracing waste reduction innovations, companies can make significant strides in their environmental impact. When you order DTF transfers, remember that these advancements not only benefit the planet but also contribute to a more efficient and responsible production ecosystem.